POM / PMMA Polishing Vacuum Mold Casting Rapid Prototypes Custom

Shenzhen Strongd does strive to help you take every good ideas to

become prototypes. We offer a variety of comprehensive services,

including CNC, SLA, SLS and 3D printing. And we are professional in

all kinds of metals and plastics rapid prototyping, vacuum casting

productions, heat forming, mold design, as well as high precision

machining.

Introduction

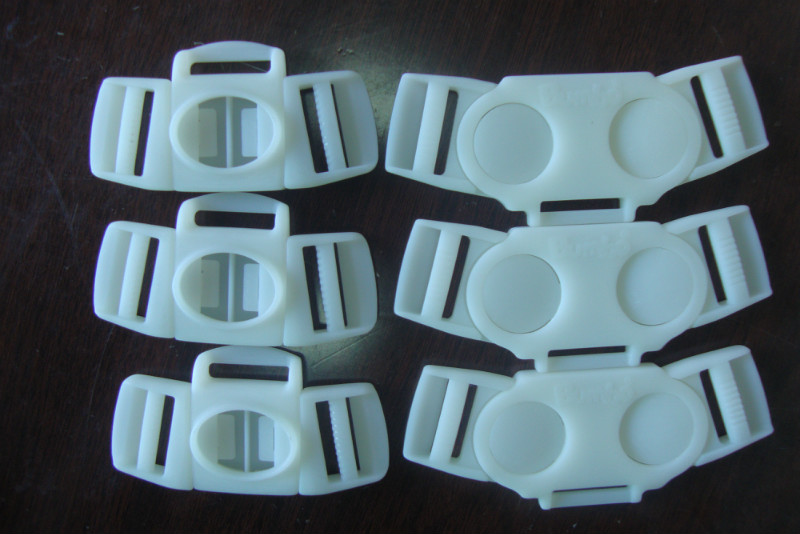

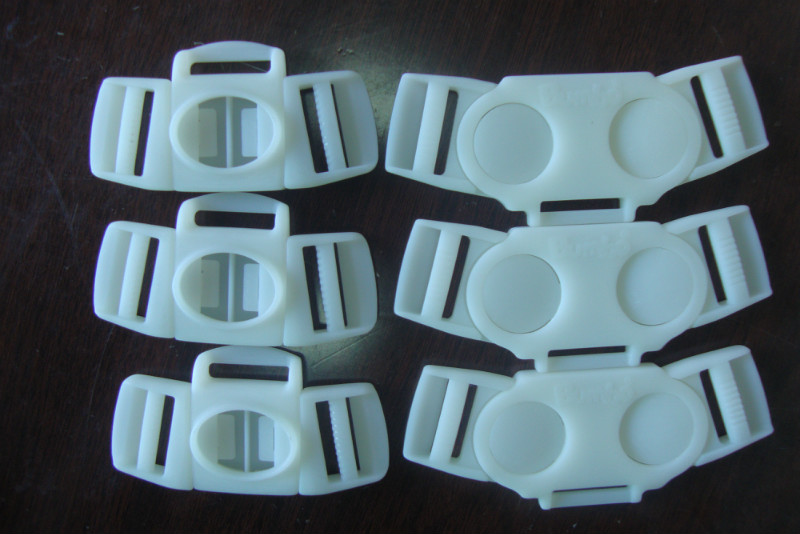

Vacuum Casting is a casting process for elastomers using a vacuum

to draw the liquid material into the mold. The process starts by

placing a two pieces silicon mold in a vacuum chamber . The raw

material is mixed and degassed and then poured into the mold.

Silicone rubber mould and small batch production model (prototype)

is one of the ways, has the advantages of fast, low cost, small

processing failure probability. Using a silicone mold can make 20

more pieces of the same product.

Size and the machinery performance are similar to steel mold

injection of products that customer needs 10-200 pieces samples,

duration and cost and not allows directly open steel injection mold

.

The most advantages of this process are the time of fast, low cost,

small processing failure probability. In order to satisfy the

customer short time get small batch test thus vacuum casting is

most ideal of solution programme .

Materials: ABS, PP, can be PC, PMMA, POM, high temperature resistant

material, soft

rubber, silicone rubber etc..

Company Information about processing ability

Precision Processing | Drilling, Milling, CNC turning, Grinding, Wire cutting, EDM & etc. |

Applied Software | PRO/E, Auto CAD, Solid Works , UG, CAD/CAM/CAE |

Material | Stainless Steel, Brass, Aluminum, Steel, Carbon Steel, Copper &

etc. |

Surface Finish | Anodize; polishing; zinc/nickel/chrome/gold plating, sand blasting,

Phosphate coating & etc. |

Dimension | As per customers' request |

Tolerance Precision | +/- 0.005--0.02mm / can also be customized. |

Part Color | Silver, Red, Blue, Gold, Oliver, Black, White & etc. |

Samples | Acceptable. |

Lead Time | Based on the quantity of order (Usually 2-3 weeks) |

Quality System | 100% Inspection before shipment |

Packing | * Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes * As customer's specific requirements |

Shipping | By sea, By air, By DHL,UPS ,TNT& etc. |

Near Port | Shenzhen, HK |

Quality Control

Strongd Tech have the best quality control system in the field of

rapid prototyping ,cnc machining .

1. we would have a detailed check of the drawings from customers in

case the files does not meet the rapid prototyping process, when

this happens , our businessman and engineers will have a meeting ,

then communicate with you to improve the drawing.

2.during the process ,our workers will strictly control The

previous oprocedure ,for example , painting workers will not paint

the part until the polish workers make the surface of the part

smooth enough .

3.We ensure regular maintenance of equipment used in the

manufacturing process and testing accuracy. All process of tracking

testing to ensure we produce all products in dimensional accuracy

requirements within limits , Including packaging and shipping, we

will also do all stages of the best.

4.our businessman will keep tracking after customer received the

parts to notice whether it met customer expectations .